Overview

Industry 4.0 a common term used to highlight the digital transformation of manufacturing, production and related industries and

value creation processes. It represents a new stage in the organization and control of the industrial value chain.

From the first industrial revolution (mechanization through water and steam power) to the mass production and assembly lines using

electricity in the second, the fourth industrial revolution will take what was started in the third with the adoption of computers

and automation and enhance it with smart and autonomous systems fuelled by data and machine learning. Industry 4.0 optimizes the

computerization of Industry 3.0. A combination of cyber-physical systems, the Internet of Things and the Internet of Systems make

Industry 4.0 possible and the smart production and manufacturing a reality. As a result of the support of smart machines that keep

getting smarter as they get access to more data, industries will become more efficient and productive and less wasteful.

Industry 4.0 takes the emphasis on digital technology from recent decades to a whole new level with the help of interconnectivity through the Internet of Things (IoT), access to real-time data, and the introduction of cyber-physical systems. Industry 4.0 offers a more comprehensive, interlinked, and holistic approach to manufacturing. It connects physical with digital, and allows for better collaboration and access across departments, partners, vendors, product, and people. Industry 4.0 empowers business owners to better control and understand every aspect of their operation, and allows them to leverage instant data to boost productivity, improve processes, and drive growth.

Industry 4.0 describes the growing trend towards automation and data exchange in technology and processes within the manufacturing industry, including:

The internet of things (IoT)

The industrial internet of things (IIoT)

Cyber-physical systems (CPS)

Smart manufacture

Smart factories

Cloud computing

Cognitive computing

Artificial intelligence

Benefits Of Industry 4.0

The benefits of Industry 4.0 include improved productivity and efficiency, better flexibility and agility, and increased profitability. Industry 4.0 also improves the customer experience.

Improved Productivity

Improved Efficiency

Increased Knowledge Sharing and Collaborative Working

Flexibility and Agility

Makes Compliance Easier

Better Customer Experience

Reduces Costs

Creates Innovation Opportunities

Increased Profitability

Higher Revenues

Flexibility

Higher flexibility is given by small batches production with the economies of scale of mass production

Quality

Improved quality and scrap reduction thanks to real-time production monitoring through advanced sensors

Productivity

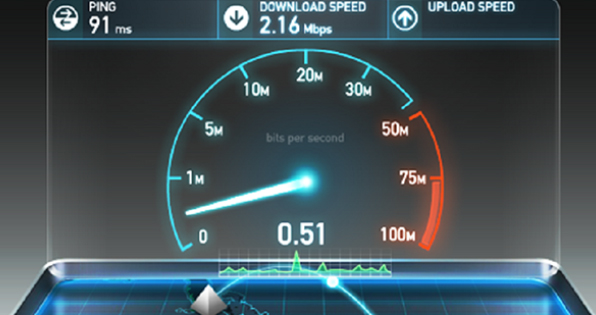

Increased productivity thanks to lower set-up time and reduced downtimes

Speed

Higher speed from prototyping to mass production using innovative technologies Increased productivity thanks to lower set-up time and reduced downtime

Product Competitiveness

Higher competitiveness of products thanks to additional functionalities enabled by the Internet of Things