- Home

- Industries

- Manufacturing

The manufacturing sector, like every other industry, faces its own set of obstacles. Although not all problems may be simply addressed,

a significant percentage of them can be overcome with proper application of technology whenever possible.

Technology intervention in the sector is not new. The introduction of the conveyor belt altered how the assembly line would function,

smoothly! Similarly, timers, counters, forklifts, robotic arms, and so on have aided in the creation of process-based industries

(such as the manufacturing sector).

Major Challenges of manufacturing industry

Forecasting Demand for Products

The key problem is that their products fail to match client demand, resulting in decreasing sales.

Inventory and project management

Inventory management is a time-consuming procedure that can be sped up using software.

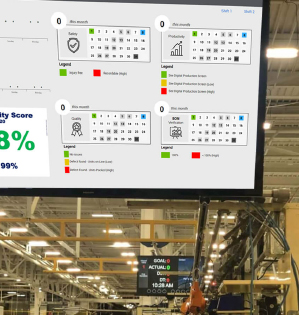

Improving Efficiency at Manufacturing Plants

Many companies prefer to forgo product quality in order to decrease production costs, but this just reduces profitability because disgruntled customers will quit buying from them.

Skilled Labor Shortage

Although automation and robotics can help close the labour gap, humans will still be required to assess and solve problems, as well as manage outputs.

Scaling up the business

One of the most difficult issues encountered by manufacturing businesses, and this may surprise you, is determining when to grow your business.

Sales Lead management

As each sales lead is unique in terms of personality, preferences, and demands, they must be handled with care.

Selling direct to customer

As more consumers use e-commerce to make purchases, manufacturing companies have been able to eliminate the middleman and sell their products directly to customers.

Maintenance and overheads

Making sure your equipment is operational and available is one of the most important production problems to tackle, along with determining your manufacturing overheads.

Increased Sales and revenue

Often, a manufacturer would boost the sales or price of its products. However, these are ineffective methods, particularly when economic conditions are volatile, lowering consumer purchasing power.

Automation in manufacturing

Finding the correct instrument to support their production operations is one of the behind-the-scenes issues that manufacturing businesses encounter.

The digital age has seemingly brought along many opportunities that businesses can leverage to make good of their investments. However, the industry still has to contend with many known as well as newer challenges – some technology-related while others are not so technical.

Ecology

- Switching off unused objects

- Use of green solution

- Renewable energy

Competitiveness

- Low manufacturing costs

- Use of innovative solutions

- Flexible response to fluctuations of demand

Flexibility

- Personalized products

- Efficient production

- Large variability in production control

Safety

- Software prevents defects

- Sensors protecting worker safety

- Immediate reaction

Productivity

- Solution to eliminate errors and wastages

- Produce more products

- Shortened cycle times

Profitability

- Advantages of mass production

- Optimized processes

- Low stock inventories and production efficiencies

Manufacturers can revolutionize their work using Industry 4.0 as it contains ample benefits. The major goal of Industry 4.0 is to make manufacturing and related industries more efficient, faster, and more customer-centric besides going beyond optimization and automation and identify new business opportunities and models.

Key benefits of implementing Industry 4.0 in manufacturing industry are:

Reduced Process Flaws

As a result of Industry 4.0-related technology, multiple parts of your production line will become more efficient.

Reduced Cost of Production & Packaging (by almost half)

To become a Smart Factory, you must invest, thus there are certain initial charges. However, as a result of Industry 4.0 technology, the cost of manufacturing at your facilities will drop considerably.

Massive Savings in Inventory & Management Costs

As a result of Industry 4.0 technology, the cost of manufacturing at your facilities will decrease.

Regulatory Compliance

Regulation compliance in businesses like pharmaceutical and medical device manufacturing does not have to be a manual procedure.

Usage of IoT in manufacturing

Automation, as well as the Internet of Things, play an important role here, as quality elements can be checked in real time and robots decrease errors.

Information-powered ecosystems of value

Industry 4.0 technologies enable your production lines, business processes, and departments to communicate independent of location, time zone, platform, or any other aspect.

Maximized productivity through automation and optimization

Industry 4.0 technologies allow you to produce more and faster while allocating your resources in a more cost-effective and efficient manner.

Improved working conditions and sustainability

Improving working conditions in the plant or warehouse based on real-time temperature, humidity, and other data, a focus on ergonomics, clean air and clean factory programmes, etc.

Real-time data for a real-time supply chain in a real-time economy

Personalization and customization for the ‘new’ consumer

Higher business continuity through advanced maintenance and monitoring possibilities

The development of innovative capabilities and new revenue models