- Home

- Consulting

- Smart Warehousing

Overview

Technology in all aspects of the economy is progressing with a rapid pace. To keep this in trend, warehouses need to be equipped with

the automation that allow them to keep up with manufacture, production, and consumer demand.

Using smart warehousing SSG helps customers to improve their productivity, efficiency, and accuracy. In addition to reduce human error,

lower risk of injury, and optimized throughput, smart warehousing reduces your overheads, adds flexibility to your HOS (hours of operation),

and allows you to be more accurate in assessing your workforce/resource.

Smart warehouses signify the switch from slow, unchanging, reactive supply chains to faster, smarter, automated systems.

Various popular tools and products are available, which can be used in your day-to-day operations, integrated for improved performance.

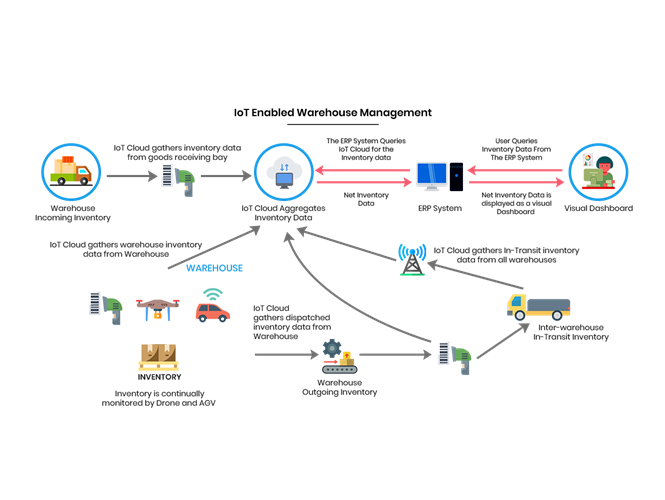

Internet Of Things For Smart Warehouse Solution

The rise in production capacity and sales market is a good news but when it comes to distribution; Warehousing is a challenge – keeping record of retailers and expansion, volume of inventory and demand mapping, loading / unloading time and many. To meet the expectation and ongoing needs of market, it is imperative for warehouses to turn towards Inernet of Things (IoT) applications. SS Global provides smart warehouse solutions - helping owners to adapt and employ smart IOT based solutions for inventory management, order processing, resource optimization, etc. Internet of Things streamlines the job and helps bringing transparency in day -to-day warehouse management work. Large organizations like, DHL, Amazon, Flipkart, WalMart, etc have achieved operational efficieincies of IoT Smart Warehouse solution.

Case study: RSBCL

Overview

Warehouses cannot be taken as a normal storage and inventory facility for businesses, but these days businesses are facilitated by smartly

digitized storage systems & played a crucial role in the completion of supply chain management. SS Global LLC as a forward-thinking IoT

leader is, therefore, introducing IoT-implicated warehousing solutions to give automated monitoring & control facilities to businesses.

SSG Smart Warehousing Solution is helpful to accelerate and empower your warehouse operations with real-time monitoring and optimizing

of warehouse assets, equipment & inventory. Our solution delivers transparency, scalability, and traceability across diverse locations.

SSG Smart Warehousing Solution gathers AI-based real-time analytics, information & data which are effectively stored in integrated cloud-based

servers. It offers meaningful insights about warehouse assets, and inventory management statuses, which helps you to get complete access

over real-time stock visibility. Our experts are highly committed to helping you leverage our IoT-enabled Smart Warehousing Systems to

increase your business profitability, bring efficiency in internal processes, enhance scalability & have complete access to the flow of

goods and inventory. Whether it is warehouse operational tasks like inventory monitoring, buffering storage, asset sequencing, or any,

our Smart warehousing solutions cover them all.

Order Management

Our Smart Warehouse technology enables you to preserve perishable goods, optimising unfinished material,

finished material & processes through order management speciality.

Smart Warehouse Solutions offer complete storage area monitoring to track & maintain safety and viability in the working environment.

Our solutions also offer automating environment control & access inside the warehouse locations.

You can effectively manage your orders with maintaining high-quality standards & procurement for product storage.

Implementation of Smart Warehousing Solution with remote automated monitoring facilities ensure that your product would follow regulatory compliance or not.

Warehouse Operation Management

Our SSG IoT-enabled Warehouse solutions monitor and access the entire route of your goods, products, starting from pickups,

to quality control, order analysis, managing order, storage and goods retrievement.

SSG Smart Warehouse solution helps you to track your inventory items and give you the clear picture of their

positive and current statuses.

It makes day-to-day operational tasks easy, convenient and effective without any human intervention.

We offer complete access to data stored in AI-based devices and prevents data loss activities.

Our solution also helps to focus on increment in order fulfillment rates, stock replenishment, labour safety.

Inventory Status

Smart Warehouse Solutions gives access and facilities to maintain a comprehensive login-logout of every entry & exit of inventories,

products and staffs from the warehouse on a regular basis.

You can effectively track the movement of inventory and materials within warehouse zones.

Smart automated programming & devices allow you to monitor the exact inventory location, areas and statuses

to prevent possibilities of misplacement or loss.

You can effectively recognise the products being transit in the wrong direction with real-time analytics & visibility.

It also provides pre-alerts or automated notifications about products transit, location or any unusual movement to the users.

Services

Sensors based technology

Using sensors to communicate real time location and item movement for better visibiltiy, helping real time decision making ability as well as forecast demand, manage invenotry and build system capacity.

Smart warehouse system

Implement Smart Warehouse and inventory management system for ease of day to day chores. Use tools for tracking, documentation, and reporting functions to support managers in effective management of goods, define employee efficiency, and handle compliance from a single platform.

Resource Utilization

Efficient use of resources like mechanized handling equipment, labour/workers, asset movements, etc

Advantages of IoT Smart Warehouse

Seamless Connectivity of assets and items

Cheaper and faster delivery management

Bring visibility to supply chain

Automating tasks for efficient resource utilization

Prevent damage and spoilage of goods

Better asset management

Data availability on fingertip

Increased decision-making analysis

Predictive maintenance of equipment

Item and product tracking in real time

Higher resource efficiency